1.Choice of the wire Rope

The choice can be made in"Table of Recommendation on Main Usages of Wire Ropes"in Addendum A in GB/T8918-1996.Considering its large rupture force,long fatigue life and good corrosion resistanded to suit soft requirements.We recommend using Liner Contact wire rope ,for the soft ,using 6x37 types.The following is some cincrete recommendations.

1)Correspendent special wire ropes for elevators.

2)Correspondent special wire ropes for building derricks with long hoisting ranges.

3)6*29Fi or 6*36SW wire ropes are adopted for short-range cranes,pile drivers,drills,electric scrapers,excavators and so on thant require good resistance against abrasion,fatigue and concussion.

4)Metal core wire rope can be chosen to suit high temperature or equipment with large rupturing load.

5)Class A galvanized woire ropes with such specs as 6*19,6*24,and 6*37 can be chosen for shipment,fishery,wood binding and so on.

In addition,the tensile strength level of the wire rope should be determined by the load and security coefficient.Any way,proper wire ropes should be determined and increase economic benefits.

2.Installation of the Wire Ropes

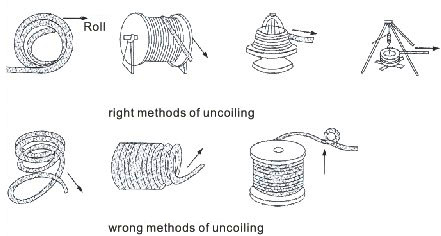

1)Uncoiling

The rope coil should be put on a special rack or a steel tube can be inserted into the central hole of the coil before uncoiling.The turn the coil slowly to uncoil.

2)Winding the Wire Rope on the Barrel

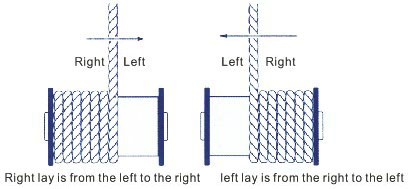

Wind the right twisted rope from left to right on the barrel and the left twisted rope from right to left on the barrel.Wind orderly to avoid deflection or clipping.

3)Cropping

Before cropping bind the rope at two places 10-20mm from the cut position for a length of 1-4 times the rope diameter.

3.Maintenance and Check of the Wire Rope

1)Operation

The wire rope should run at a stable speed,avoiding excessive load or impact.

2)Maintenance

Enough oil or grease has been rubbed on the surface of the wire rope,but after some times of running,the oil or grease will reduce gradually,dust and crumbs will taint the surface,causing attrition between the rope and the pulley and rust on the rope.So regular cleansing and oiling should be exercised. A simple method is to scrub away dust and crumbs with a steel wire brush,then rub melted grease on the rope surface or pour 30# or 40# machine oil on the surface but prevent excessive oiling to avoid environmental pollution.

3)Checking Record

The wire rope must be checked regularly on oiling,attrition,wire rupture,corrosion,and damageable parts and the checking result must be recorded.On finding abnormal conditions,necessary replacement must be made.

Steel Wire Rope Lubrication

DESCRIPTION

LubMaster Grease is a blend of high viscosity petroleum base oil with shear stable lithium soap thickener,fortified anti wear,anti rust with unique additives package combine to achieve high performance and year-round utility lubricant for wire ropes.This results in longer wire rope life,less downtime for rope changes and enhanced productivity.

TYPICAL APPLICATION

Lubrication and maintenance of draglines,towing cables,pendant ropes and other offshore applications can be simplified by use of LubMaster Grease.

BENEFITS

Solid additives package are pre-activated to increase their natural positive affinity to all metal surfaces to ensure easy lubricant applications for extended re-lubrication intervals. Solid additives package are pre-activated to increase their natural positive affinity to all metal surfaces to ensure easy lubricant applications for extended re-lubrication intervals.

Polymer allows flexibility to external coating for wire rope in harsh environments. Polymer allows flexibility to external coating for wire rope in harsh environments.

Bonding and cohesive properties provide superior lubrication to withstand wet corrosive conditions. Bonding and cohesive properties provide superior lubrication to withstand wet corrosive conditions.

Scientifically designed for self-sealing protection,keeping ropes from dust and dirt build-up. Scientifically designed for self-sealing protection,keeping ropes from dust and dirt build-up.

Long lasting dressing formed to resist fling-off and cracking. Long lasting dressing formed to resist fling-off and cracking.

NOTES

LubMaster Grease is not compatible with sodium or inorganic base greases.

Best performance when applied with Mastro Spray (Compress Air Assisted Method ensures penetration to Wire's centre core strand).

This information in this bulletin is,to our best knowledge,true and accurate,but all recommendation or suggestions are made without guarantee,since the conditions of use are beyond our control.It is the user's obligation to evaluate and use the product safety and to comply

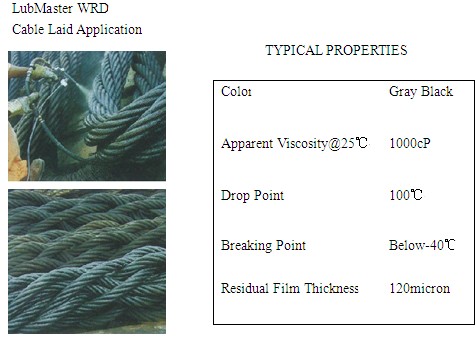

Steel Wire Rope Lubrication

DESCRIPTION

LubMaster Wire Rope Dressing (WRD) COMPOUND is a semi fluid grease,specifically formulated wax/polymer lubricant,that is totally water repellent.

Wire ropes contain numerous moving parts which require lubrication.Each time the rope bends or flexes,the internal strands rub together.LubMaster WRD ensures that the rope is lubricated throughout while providing a nondrying,non-tacky film on the outside of the rope.Such protects outer strands from corrosion as well as lubricates the wire rope drums and sheaves.

Compound coats wire rope strands externally to prevent friction and wear.Dressing that is aromats free has good creeping capability to IWRC (Steel Core)ropes core resulting in longer wire rope life,less downtime for rope changes,and enhanced productivity.

TYPICAL APPLICATION

Hoists,Cranes,drag lines,offshore wire ropes in extreme or harsh environments. Hoists,Cranes,drag lines,offshore wire ropes in extreme or harsh environments.

Wire ropes running or standing, being used at ports and ship loader facilities. Wire ropes running or standing, being used at ports and ship loader facilities.

Rust protection for all exposed metal surfaces. Rust protection for all exposed metal surfaces.

BENEFITS

Unique wax/polymer formulation forms pliable external coating. Unique wax/polymer formulation forms pliable external coating.

High treat level of anti-rust additives eliminates corrosion problems in the harshest environments. High treat level of anti-rust additives eliminates corrosion problems in the harshest environments.

Low viscosity base fluid,coupled with penetrating agents,provide complete internal penetration and protection to ropes. Low viscosity base fluid,coupled with penetrating agents,provide complete internal penetration and protection to ropes.

Thixotroping agents minimize dripping and fling off. Thixotroping agents minimize dripping and fling off.

NOTES

Can be applied by brush or drip,but preferaby sprayed to activate thixotrope. Can be applied by brush or drip,but preferaby sprayed to activate thixotrope.

This information in this bulletin is, to our best knowledge,true and accurate,but all recommendation or suggestions are made without guarantee,since the conditions of use are beyond our control.It is the user's obligation to evaluate and use the product safety and to comply with all applicable laws and regulations.

|